Robotic equipment in manufacturing includes Robots, which change the position of objects in space, and Tools, which perform various technological operations. All these controlled devices transform incoming workpieces into a finished product – either a means of life or a means of labor. On the other hand, some components of technological equipment are not controlled, for example setup tables, containers, and accumulators.

In the representation of the industrial platform, the above categories belong to Parts, whose distinguishing feature is the absence of any direct connection to the production control system: they do not execute any programs and do not return data about their state.

In this article, we will consider the creation of a set of parts for performing the operation of assembling spline joints.

Junction

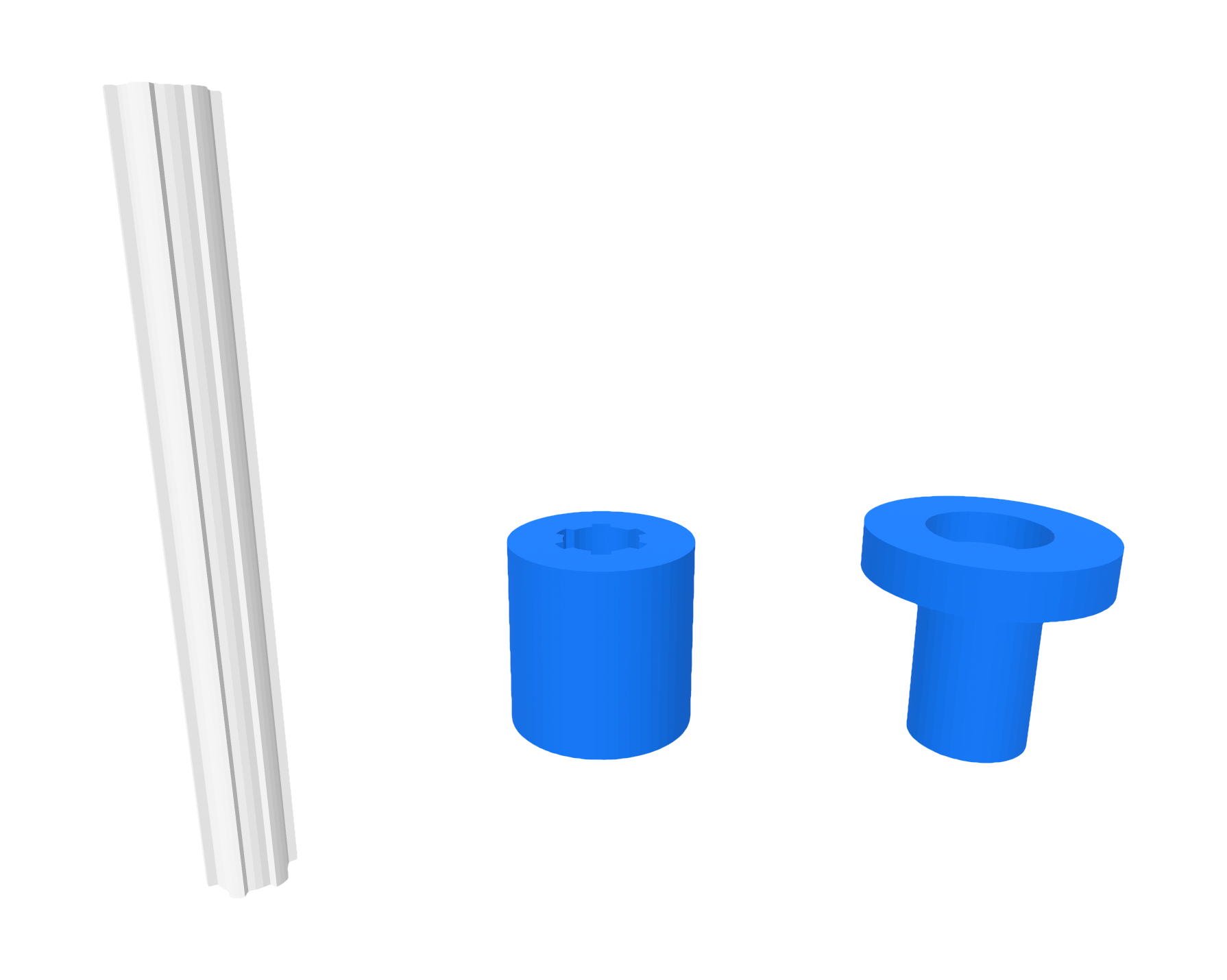

A spline joint consists of two parts – a shaft and a bushing. Since the solution is being developed for real production, the parts are chosen from among existing offerings. After selecting parts suitable for the equipment of the laboratory robotic cell – a shaft and the corresponding bushings (without and with flange), we find the drawings provided by the manufacturer and create models based on them in STL format.

It should be noted that selection is usually two-sided – just as equipment is chosen for a technological process, so the process is adapted to the equipment.

The ready-made part models are added to the STC package, where a set of corresponding modules is created – Spline Shaft, Spline Bushing, and Spline Bushing F. For each module, its own SCN scene and default physical body parameters are specified.

The models are also used for 3D printing of sample parts intended for testing the assembly process in the laboratory – damaged samples can easily be replaced with newly printed ones.

Fitting

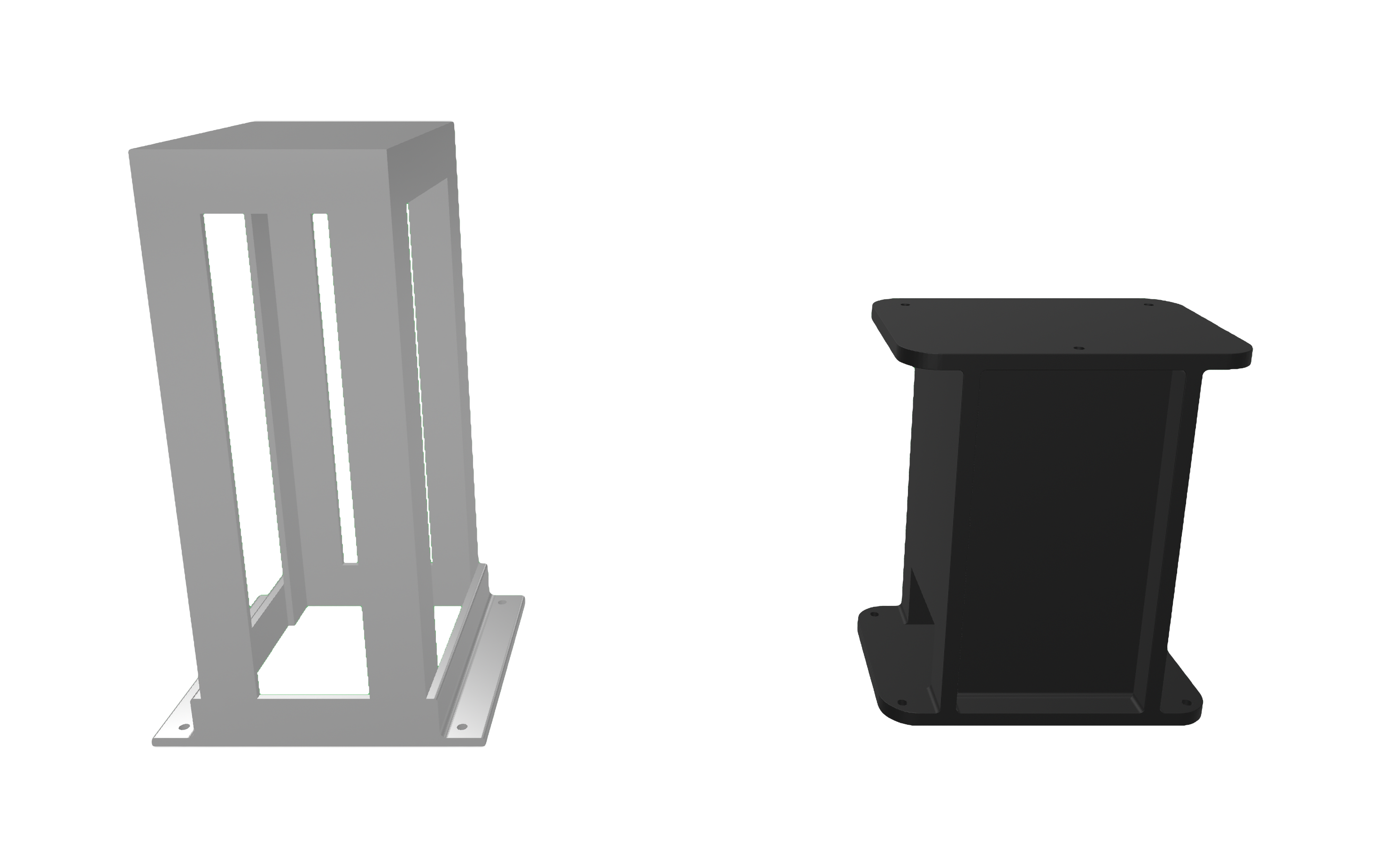

Passive means of labor include setup tables – one for the robot manipulator, the other for the assembled parts.

These modules are used to create a more accurate model of the robotic system, and in the absence of models they can be replaced with simple geometric primitives of specified dimensions or omitted entirely – the robot manipulator and the bushing are always assumed to be rigidly fixed.

Since the setup table models were provided by the university, all that remained was to convert them into the appropriate format (STL) and add them to the existing modules in the STC package.

Build

Since the parts are not controlled and, accordingly, do not use any algorithms, their compilation is minimal – the models are simply assembled into a single module package together with a header.